Smart Mechatronics

OHB Digital Connect is an expert in the precise positioning of large and heavy structures of all kinds. As a reliable partner with many years of experience in the construction of large antennas and radio telescopes, we combine comprehensive know-how in the fields of mechanics, steel construction and control technology to generate customized solutions for a wide range of applications.

OHB Digital Connect at the Mainz site (formerly MT Mechatronics) has been developing mechatronic systems for the submillimeter-precise alignment and positioning of objects weighing several tons for a wide range of industries since 2007. Most other mechanical engineering companies are unable to achieve this level of performance, which we routinely provide in the construction of large antennas and radio telescopes. Applications that require such precision include XXL computer tomographs for non-destructive material testing, as well as proton and heavy ion portals for modern cancer therapy centers.

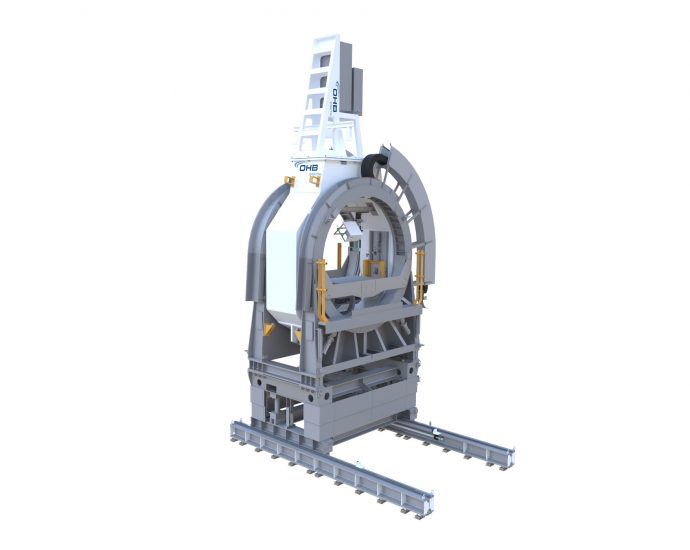

XXL Computer Tomographs

In cooperation with the Development Center for X-ray Technology (EZRT) at the Fraunhofer Institute in Fürth, we develop and build extra-large computer tomographs. These modern systems are used, for example, to scan vehicles, containers or concrete samples and display their internal structures in detail in a 3D model.

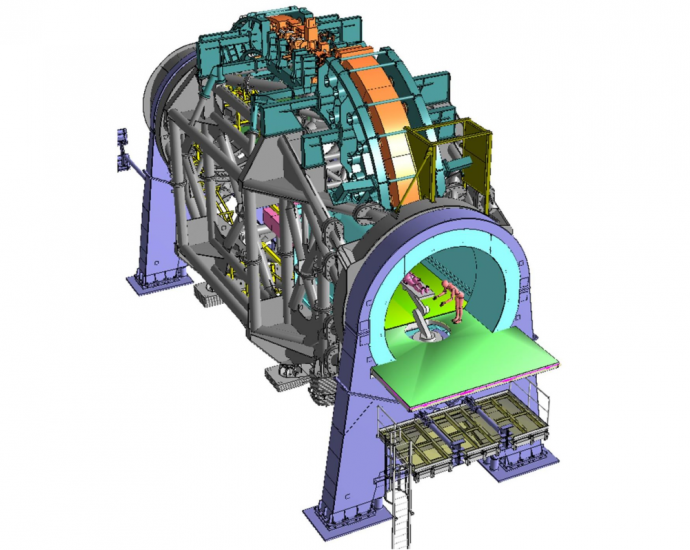

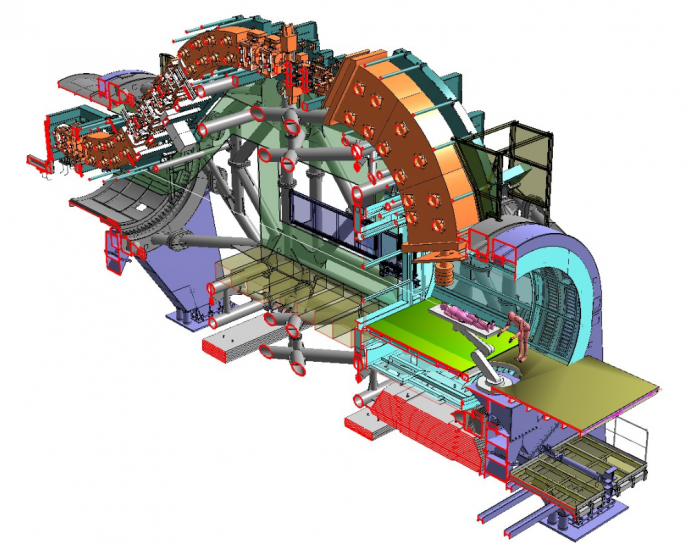

Proton and Heavy Ion Portals for Modern Cancer Therapy Centers

We have developed and supplied high-precision gantries for the next generation of facilities for cancer therapy with proton and ion particles, including a turnkey ion gantry for the Heidelberg Ion Therapy Center.

Our commitment to precision engineering and technological advances drives us to constantly push the boundaries. Experience innovation and excellence first hand.

Would you like to find out more about us and a possible collaboration?